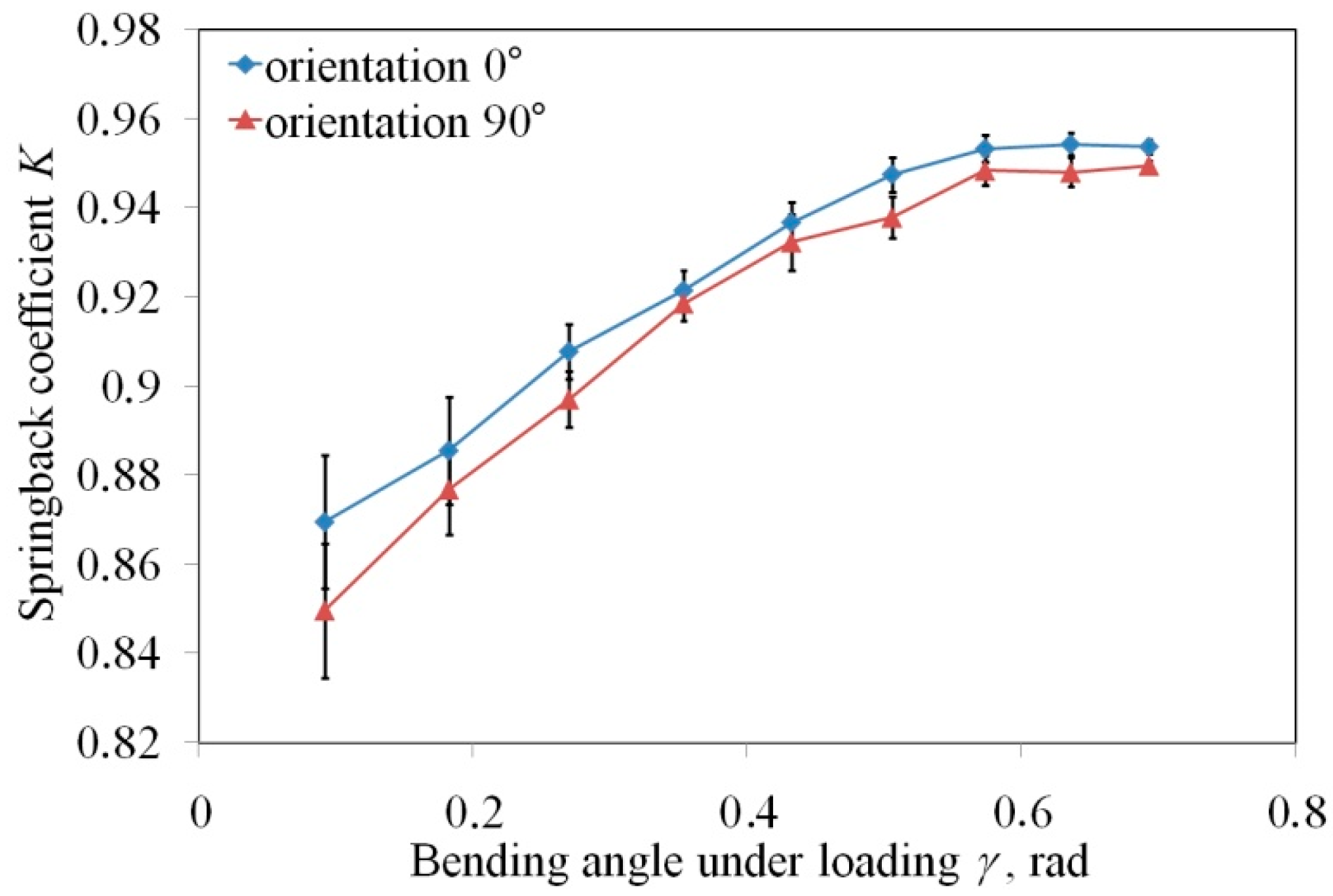

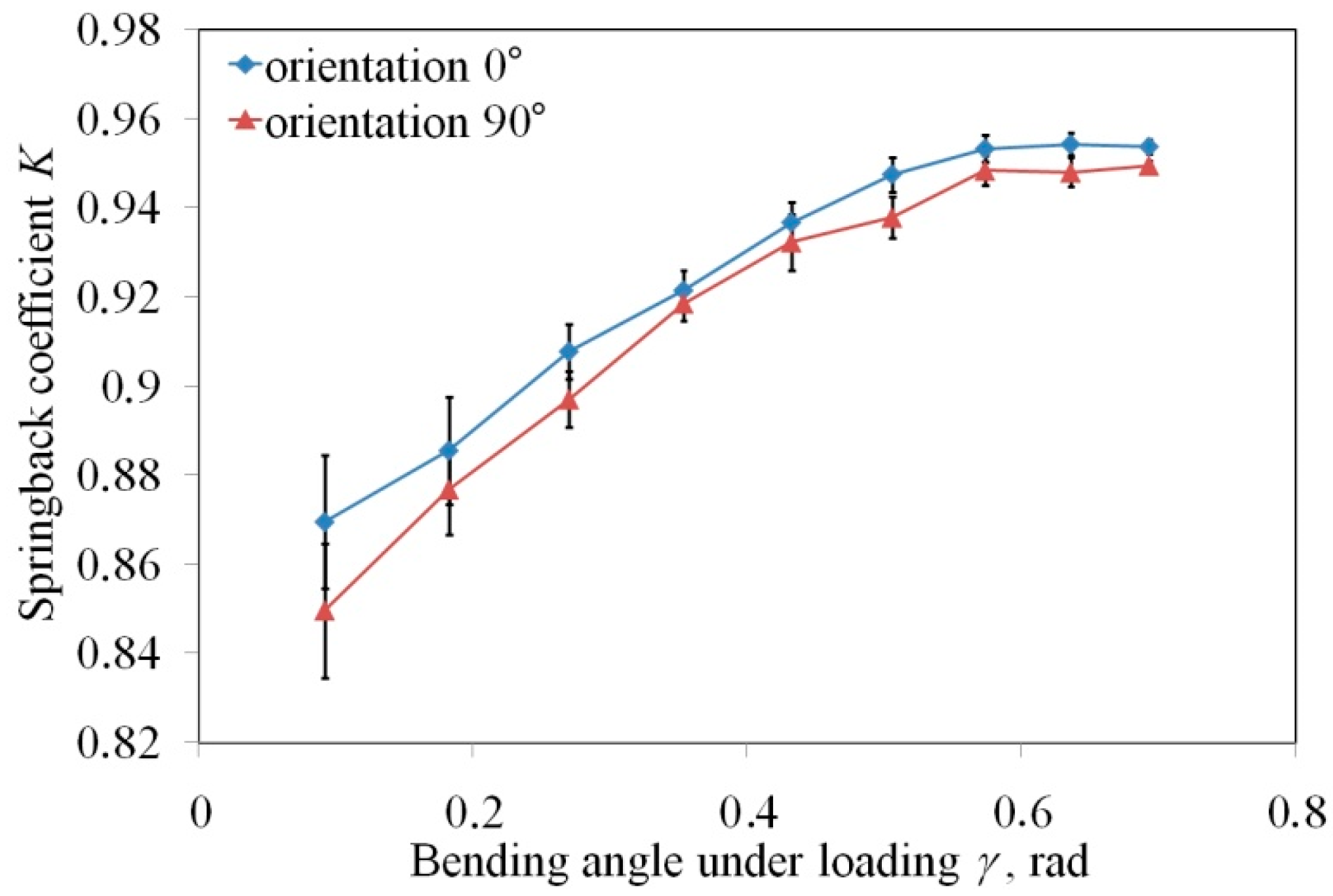

Springback and inside radius calculator for sheet metal.

Determination of springback in sheet metal forming.

Springback is how the sheet metal tries to revert back into its straight form once it is bent.

Considering springback occurred in a formed part is significant for designing tools and dies.

During each sheet metal forming process the high strength steels exhibit distinct springback effect which is governed by strain recovery of material after load removal.

The formation of sheet metal requires elastic plastic bending and stretching of the metal which contributes to springback.

The springback consists of assumed elastic unbending on removal of the applied moment.

The springback is variably sensitive to materials and process parameters.

Bending is one of the most frequent actions done to metal in press brake operation.

During forming the material is strained beyond the yield strength in order to induce permanent deformation.

Springback is inherent in sheet metal forming.

When the proportional limits of a specific material are reached or exceeded the material remains bent figure one.

Springback is known as the reaction when this metal is bent and causes complications when forming the metal into objects such as seams and flanges.

Finite element simulation of sheet metal forming is a well established tool which is used in industrial practice to evaluate geometrical defects caused by elastic springback.

This springback and inside radius calculator estimates the amount of angular change and the relaxing of bend radius that occurs when metal is bent and released from pressure.

However the adoption of the isf process in industry is largely hampered by its limited geometric accuracy caused by multiple sources e g tool compliance addressed in.

This phenomenon results in a deviation of the real product geometry from that defined in the design.

Upon completion of sheet metal forming deep drawn and stretch drawn parts spring back and thereby affect the dimensional accuracy of a finished part.

Springback springback is the geometric change made to a part at the end of the forming process when the part has been released from the forces of the forming tool.

Springback it is instructive to begin with the simplest case and the most restrictive assump tions.

Springback can be defined as an elastically driven change of shape of the deformed part upon removal of external loads.